SPACEX #17 - WTF is with the LNG unit that can fuel 300+ Starship Launches Per Year?

GigaStarbase

🚨Here’s your SpaceX NEPA 101 guide for context and background- READ THIS FIRST🚨

CHAPTER 17: LNG is LNG, and Rocket Fuel is LNG

Last week, I posted about how the VOC emissions at the SpaceX Boca Chica facility clearly indicate that that they intend to treat field (or wet) natural gas from a gathering system (fracked gas wells, flares and pipelines) that doesn’t exist.

We had two interesting public comment meetings this week. The highlight for me was my brief speaking role and shout out from Space Journo Eric Berger:

Let’s ignore the fact that while, yes, I was muted at exactly 3 minutes, many others went more than a minute over. Regardless of his intent, Eric did inadvertently point out to thousands of people that my research and writing was news to many as my Twitter mentions were flooded with claims that I was a lunatic spinning conspiracy theories.

Despite the fact that a 200 foot demethanizer1 column is clearly the central processing piece in a large gas plant used for treating field gas, despite the fact that pipeline quality natural gas is already 98% plus methane and nearly completely devoid of VOC2s as is (<0.05%), there still seems to be this rather large contingent on the internet who thinks SpaceX’s gas pretreatment system is some rinky dink little thing used for processing a few truckloads of natural gas and upgrading it to 100% pure methane, which has transcended the term Natural gas and is now LCH4 rocket fuel, an elixir of the Gods, used to elevate Starship into the heavens. So let’s walk through that theory.

The Eagle LNG Plant

Let’s talk about an LNG terminal that’s on the smaller side compared to the large Cheniere or Kinder Morgan operations. The Eagle LNG terminal in Jacksonville, Florida. There are a few reasons I picked this site, which will become apparent shortly.

Eagle LNG submitted paperwork in January 2017 to FERC for a 1.5 million gallon per day LNG treatment and bunkering export terminal on the St. John’s river. This was after a year of public meetings, studies and preliminary engineering. The project was granted approval (using NEPA!) in December, 2020, nearly 3 years later.

The facility would have 3 process trains, each sized at 500,000 gallons of Liquid Natural Gas (LNG) per day. The facility would take pipeline quality gas, via a pipeline interconnect, run it through an Amine Treatment system (CO2 and Mercaptan removal) a glycol dehydrator (water removal) as well as a small hydrocarbon knockout vessel. The gas would then be supercooled and liquified and the LNG would be exported out via truck or tanker. The plant is an all in one solution developed and engineered by Chart Industries, who specializes in these modular LNG systems. Simple, right?

The resulting liquid is 99%+ methane, completely devoid of CO2 and water. So I think that’s rocket fuel, but I’ll have to check with the rocket science understanders on that one.

This sounds a lot like the SpaceX solution, according to the people who decry me as a lunatic, right? Maybe the gas comes in by truck even, since there’s no pipeline and one isn’t mentioned at all in the FAA Programmatic Environmental Assessment. Let’s take a look at a single one of these Chart Industries trains and play out that scenario.

500,000 gallons per day is about 750 million pounds per year of pure liquid methane. I’m told that Starship will burn 1000 metric tons per launch, meaning that this one single train could provide enough LNG, I mean beautiful rocket fuel, for 337 launches per year! That’s nearly one launch per day.

“That’s overkill, though, ESG Hound.”

I’d be inclined to agree, but let’s take a closer look. Since the presumption is that SpaceX isn’t drilling for a bunch of natural gas, and someone suggesting such a thing would be crazy, there would be no need to turn pipeline quality natural gas into LNG and then turn around and re-expand it for use in the 250 Megawatt power plant3 right next door. Even if that were the case, the power plant running 24/7 at close to max capacity would consume 80% of the LNG, leaving enough rocket fuel for only 68 launches per year.

“Ok that’s overkill, right?”

You’d sure think so. Let’s take a look at the processing and transfer emissions to create 750 million pounds of rocket fuel quality LNG from regular natural gas. This is straight out of the FERC filing and Chart Industries technical data.

Now, keep in mind this facility is overkill. And it does all that we want. Makes rocket fuel from pipeline natural gas. No extra natural gas pretreatment facility complete with a 200 foot tall demethanizer.

Now, let’s take a look at these emissions vs those from the projected SpaceX “natural gas pretreatment process” and “liquefier.”

Hmm. This seems very odd. Remember that pipeline spec natural gas is already nearly devoid of VOCs, whereas gas straight from newly fracked wells is 10-20% VOCs by mass. The Eagle LNG plant is a liquefier with a few small add on amine and hydrocarbon knockout units, whereas the SpaceX facility seems to be something much… more complex?

The Chart Connection

In the Q4 2020 Chart Industries earnings call, held in February 2021, a few interesting things showed up. First, the company announced that it had several first of its kind orders, including in the specialty Space industry. They all of the sudden had a $200 million Near Term Total Addressable market in Space, with this graphic:

The project backlog included this new entry:

Remember that SpaceX had the initial scope for this project determined in November 2020 (e.g. Chart Industries’ Q4). SpaceX is also a past Chart Industries customer.

Here’s the kicker:

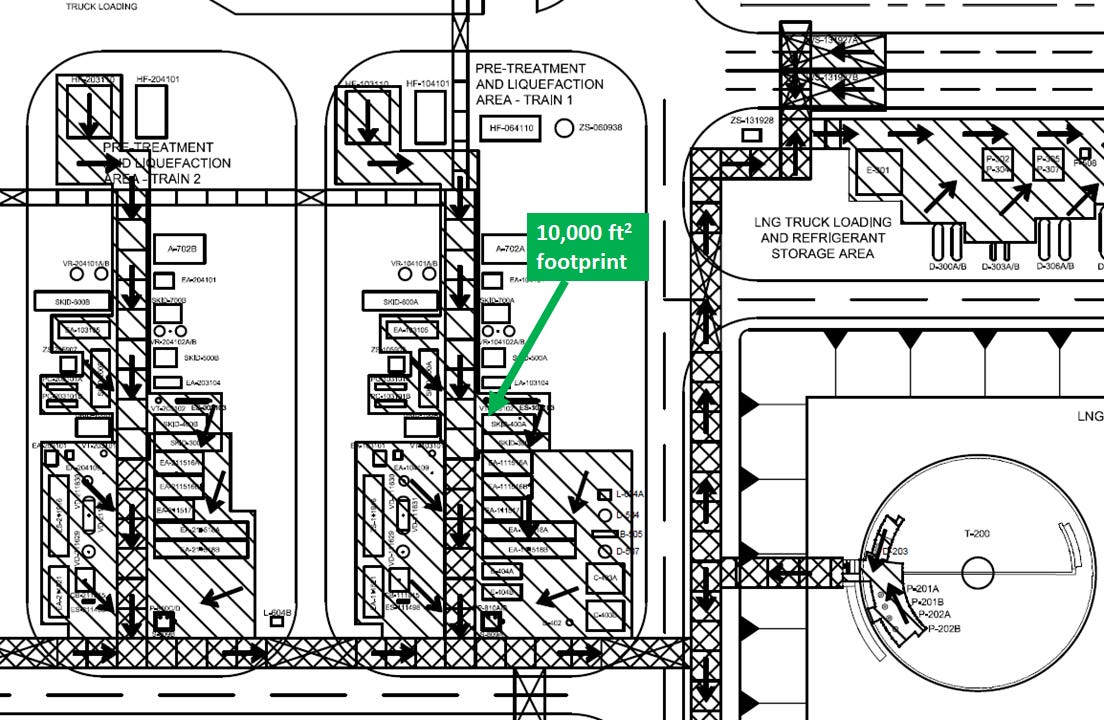

You know what else has a similar footprint (10,000 sq ft) and similarly sized vertical heat exchanger4 (30 ft tall)?

If you guessed a single Eagle LNG Processing Train, made by Chart Industries, YOU WIN A PRIZE!

Now, let’s discuss. I can’t guarantee that SpaceX ordered a Chart LNG plant. But the sizing alone suggests that SpaceX’s two liquefiers (LNG and LOX) are rather large units.

And, again, the VOC emissions suggest strongly, if not outright prove, that SpaceX intends to treat well natural gas in the Pretreatment Process and then liquify the processed gas afterwards.

The problem is: there is no well gas nearby. And there’s no pipeline.

The fact that the source of the facility’s input fuel isn’t even mentioned in a NEPA document is a huge 🚩red flag🚩, and I keep finding evidence to suggest that the reasons for this exclusion aren’t accidental.

SpaceX wants to get into the oil and gas business, from well to flame, with all the mess that comes along with it. FAA seems all too happy to allow it. And they’re all too cowardly to admit it. For Shame.

BONUS CONTENT:

Read up over At Doomberg why natural gas is already nearly pure methane. Hint, it’s because Ethane is wasted in combustion. Ethane is the input molecule for Ethylene Oxide production, which is in turn used to make, well… everything:

Also this doesn't merit its own post, but SpaceX’s own rocket plume data includes C2 (ethane) combustion products, meaning even they know that their LCH4 will have some ethane in it:

PART 1 - NEPA Primer / FAA has no business permitting oil and gas facilities

PART 2 - Elon Musk’s Natural Gas Treatment Plant

PART 3 - SpaceX is building a pipeline and doesn’t feel the need to mention it

PART 4 - SpaceX dreams of drilling for a sh*tload of oil

PART 5 - A discussion on the hugeness of the project, a parade of tankers and a reality check about the Oil and Gas biz

PART 6 - The Facility would be a Major Source of Pollution under the PSD Rules in the Clean Air Act, which by statutory definition would exclude it from fast track approval under NEPA

PART 7 - The GHG and CO2 emissions are plainly nonsense

PART 8 - ESG Hound drops the gauntlet and explains why this is a massive fraud happening in plain sight.

PART 9 - The End of NEPA as we know it

PART 10 - ELON MUSK REALITY DISTORTION FIELD

PART 11 - Pipeline Plans Confirmed!

PART 12 - It turns out drilling for oil and gas has some negative environmental impacts

PART 13 - I found the Modular Gas Plant; the clue that got me there will leave you stiff with shock

PART 14 - The wildlife toll of industry, told through my personal experiences

PART 15 - SpaceX is building an LNG, does anyone care?

PART 16 - First Principles and gas processing plants

No one calls them deethanizers in context of cryo gas plants so I will stubbornly continue to call it by the industry name.

Volatile Organic Carbons, which for air permitting purposes are propanes (C3) and heavier. Ethane and Methane are not ozone precursors so they do not get the same treatment.

You can’t burn anything in utility sized natural gas turbines except for pipeline quality natural gas or equivalent (biogas, etc)

The Chart Heat Exchanger size is <30 ft, but can be placed in an insulated Cool Box, adding additional length.